10 Summer Maintenance Tips to Keep Your Generator Ready

As summer rolls in, extreme heat and severe weather events can roll in right along with it. Extreme heat drives up electricity demand, which can strain the power grid and increase the chances of unexpected outages.

Severe weather events can cause widespread and long-term power outages that can bring operations to a halt, forcing businesses to shut down temporarily or even permanently.

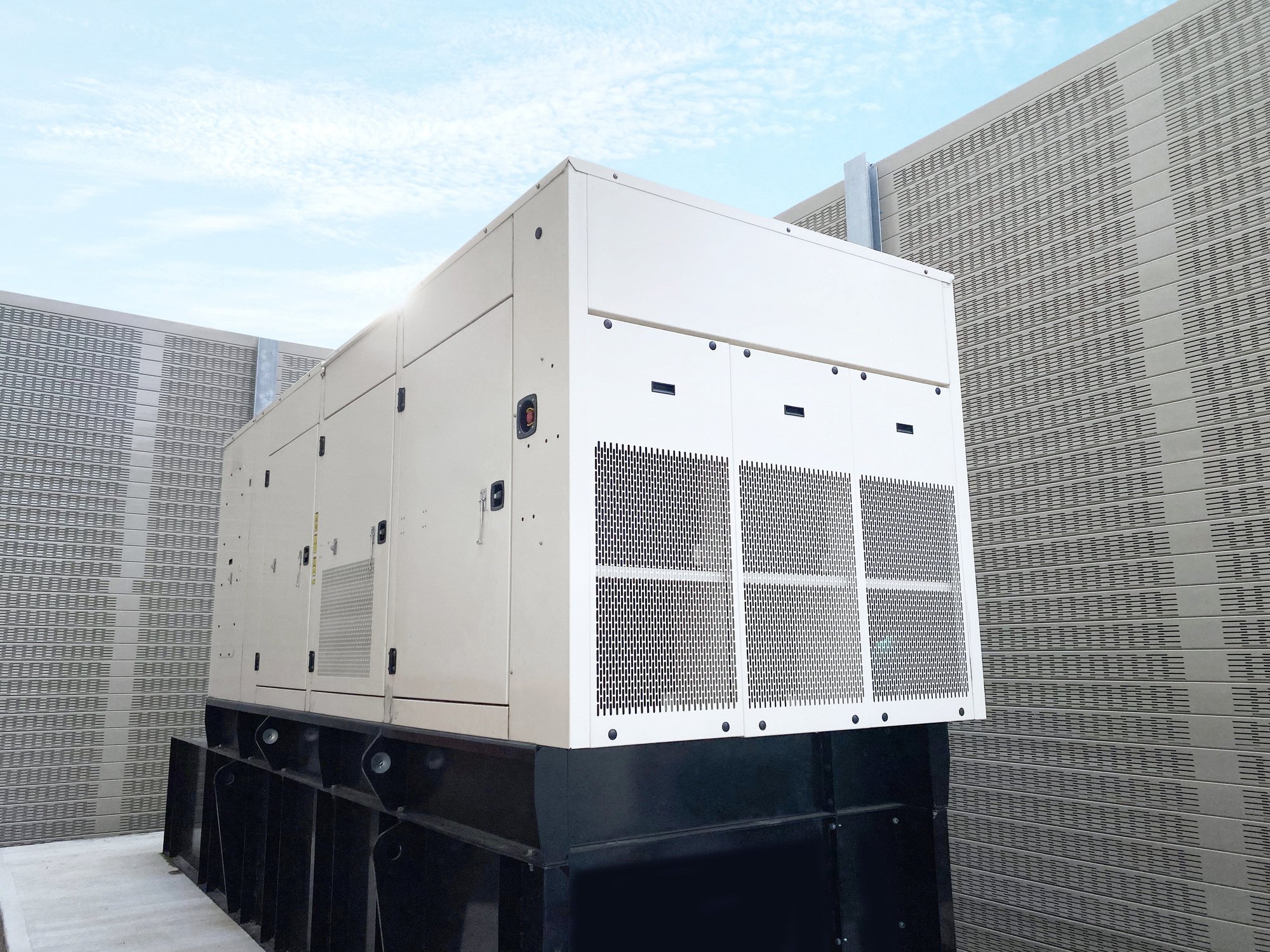

The good news is you have a backup generator to keep your business running should a power outage occur. But have you stayed on top of its maintenance so it’s ready for action this summer?

“Summerizing” Your Generator

Keeping your generator in optimal condition is crucial to ensuring a reliable power supply when you need it most. Just as your fleet vehicles need special considerations and maintenance in summer to ensure optimal performance and longevity, so does your generator.

With summer temperatures expected to be far warmer than average across much of the nation and the 2024 Atlantic hurricane season predicted to be one of the most active on record, the chances are that power outages could be more frequent.

Protect your business, employees, and customers by ensuring your backup power source is ready to kick in when the power unexpectedly goes out. Following these summer maintenance tips will help you accomplish that.

1. Conduct Regular Inspections

Summer heat and dust can be hard on generators, which makes routine inspections crucial for identifying potential issues before they become problems.Check for signs of wear and tear, corrosion, and leaks. Check components such as the fuel system, coolant levels, and electrical connections. Look for signs of fraying or cracking in hoses and belts.

2. Test the Battery

Because heat can quickly degrade battery life, it's important to regularly test your battery to ensure that it can hold a charge and provide adequate power. Clean the battery terminals and check for signs of corrosion. If the battery is over three years old or shows signs of weakening, replace it.

3. Check the Coolant System

If the coolant system isn’t functioning properly, high temperatures can cause the generator's engine to overheat. Check coolant levels and top up if needed.

Inspect the coolant hoses for leaks or cracks, and ensure the radiator is clean and debris-free. Additionally, use a coolant mixture appropriate for summer temperatures to help keep the engine cool and prevent overheating.

4. Change the Oil and Filters

Regular oil and filter changes are essential for keeping your generator running optimally. Summer heat can cause oil to break down faster, which reduces its effectiveness for lubricating engine parts.

Follow the manufacturer’s recommendations for oil change intervals and use high-quality oil suitable for high-temperature operation. Replace the oil filter so there are no contaminants present that could cause engine damage.

5. Clean or Replace Air Filters

Air filters are crucial in maintaining engine efficiency by trapping dust and debris from the air intake. In summer, there’s more dust in the air, and air filters can become clogged more quickly.

Inspect the air filters regularly and clean or replace them to ensure optimal airflow and prevent the engine from overheating or losing power.

6. Check the Fuel System

Fuel quality can degrade quickly in hot weather, which can cause deposits that clog the fuel system and fuel contamination. Inspect fuel lines, tanks, and filters for signs of wear or contamination. Use a fuel stabilizer to maintain fuel quality and consider draining and refilling the fuel tank if the generator has been idle for an extended period. Regularly check for water in the fuel system, as condensation can occur in hot and humid conditions.

If you have any questions regarding fuel integrity, testing, and emergency fuel delivery, a call to your fuel provider is the proper course of action to take.

7. Test the Generator Under Load

Running your generator under load for a short period can help ensure it’s functioning properly and is capable of handling your power demands. It will also help you identify any issues related to fuel delivery, electrical output, and cooling systems.

8. Inspect the Transfer Switch

The transfer switch transfers power from the utility source to the generator during an outage. Check for signs of wear or damage. Test the switch to verify it can transfer load smoothly and efficiently.

9. Keep the Area Maintained

Ensure that the area around the generator is clean and debris-free, which can restrict airflow and increase the risk of overheating. Keep vegetation and flammable materials away from the generator to reduce fire risk. Regularly clean the generator’s exterior and ensure the ventilation openings aren’t obstructed.

10. Schedule Professional Maintenance

While routine checks can be handled in-house, scheduling regular professional maintenance is always a good idea. Technicians can conduct in-depth inspections, perform diagnostics, and address issues that require specialized knowledge or tools. Professional maintenance can significantly extend the lifespan of your generator and ensure safe and reliable operation.

Want to take these tips with you? Download our generator fuel and maintenance checklist to ensure your generator is always emergency ready.